The Future of Innovation and Technological Trends in 4 Pin Terminal Blocks

Introduction:

As technology continues to evolve, innovations in the field of electrical connections have become increasingly crucial. In this blog post, we will explore the latest advancements and future possibilities in 4 pin terminal blocks. These versatile connectors play a crucial role in various industries, offering reliable and secure connections for diverse applications. We will delve into the benefits and characteristics of 4 pin terminal blocks, including the 3 pin screw terminal, 3 position terminal block, 4 pin terminal, 4 pin terminal block, terminal block 4 pin, and the 4 pin terminal block connector.

Enhanced Versatility with the 3 Pin Screw Terminal:

The 3 pin screw terminal is a fundamental component of the 4 pin terminal block. Its design ensures easy and secure connections, making it a preferred choice for many industries. Whether you are working on industrial automation or robotics applications, the 3 pin screw terminal provides reliable and efficient electrical connections, enabling seamless integration and operation.

Precise and Convenient Wiring with the 3 Position Terminal Block:

In applications requiring multiple connections, the 3-position terminal block shines. With its compact design and clear labeling, it simplifies the wiring process and prevents potential mistakes. The 3 position terminal block offers flexibility while maintaining a high level of accuracy, making it an ideal solution for control systems, sensor connections, and other complex setups.

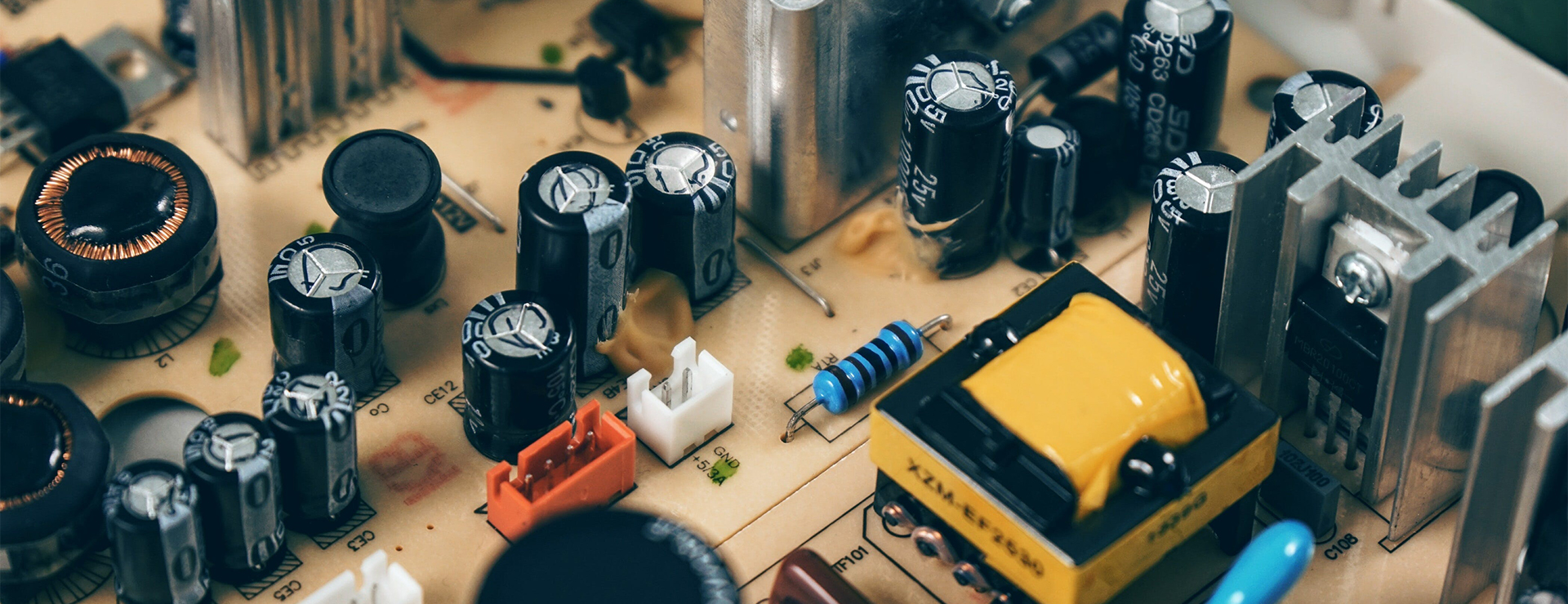

Power and Reliability with the 4 Pin Terminal:

The 4 pin terminal serves as the backbone of the terminal block, delivering power and stability. Its robust construction ensures long-lasting performance in challenging environments. Capable of handling high currents and voltages, the 4 pin terminal remains a key component in various industries, including automotive, renewable energy, and machinery.

Secure Connections with the 4 Pin Terminal Block:

The 4 pin terminal block combines the convenience of screw-type connectors with the reliability of a terminal block. It offers a secure and vibration-resistant connection, minimizing the risk of disconnection or signal loss. With its compact size and versatile design, the 4 pin terminal block facilitates efficient wiring in applications ranging from control panels to lighting fixtures.

Optimal PCB Integration with Terminal Block 4 Pin:

PCB terminal blocks have revolutionized the electronics industry, and the 4 pin terminal block is no exception. With its PCB mountable design, it enables seamless integration onto circuit boards, saving space and reducing assembly time. The terminal block 4 pin ensures reliable connectivity between PCBs and external components, providing a cost-effective solution for manufacturers.

Seamless Connectivity with the 4 Pin Terminal Block Connector:

The 4 pin terminal block connector serves as the bridge between different devices and modules. Its plug-and-play functionality allows for quick and hassle-free installation. By providing a secure and standardized connection, the connector facilitates efficient communication and interoperability. It is a vital component in applications such as robotics, automation, and IoT systems.

In the rapidly evolving landscape of electrical connections, HONG YI-HOMNECKS+PCB Terminal Block emerges as a market leader. Their commitment to innovation, advanced technologies, and exceptional service sets them apart. With their comprehensive range of 4 pin terminal blocks, including the 3 pin screw terminal, 3 position terminal block, 4 pin terminal, 4 pin terminal block, terminal block 4 pin, and the 4 pin terminal block connector, HONG YI-HOMNECKS+PCB Terminal Block continues to provide industry-leading solutions that deliver reliable connections and meet the evolving demands of the market.