Why is lighting important in hotel industry?

Lighting in the hotel industry is more than illumination - it is a strategic tool that influences guest satisfaction, brand identity, safety, functionality, and operational efficiency. From lobby to guest room, proper lighting transforms a simple stay into a memorable experience.

Here is a breakdown of why lighting is so vital in hospitality:

1. Enhance Functionality and Guest Comfort

A hotel must cater to a variety of activities, and lighting makes this possible.

* Ambient Lighting: Table lamps, floor lamps, and ceiling lights provide general ambient lighting which is essential for the overall environment.

* Task Lighting: Focused light from desk lamps, adjustable reading lights, and illuminated vanity mirrors ensures guests can read, work, or apply makeup comfortably.

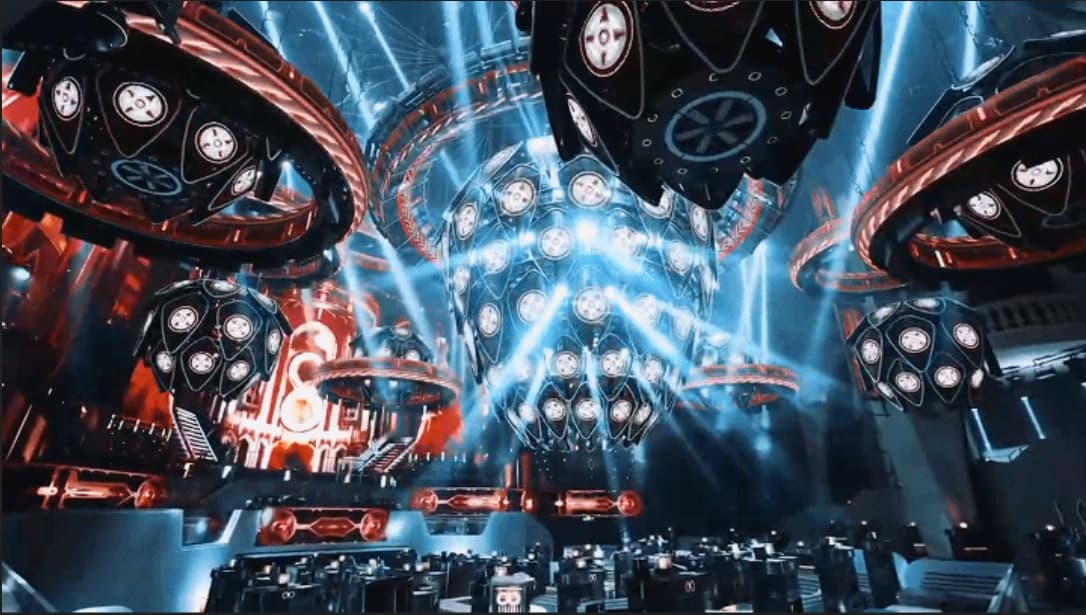

* Decorative Lighting: A statement chandelier or warm cove lighting in lobby immediately conveys luxury, comfort, and attention to detail. In conference rooms and ballrooms, adjustable lighting supports multiple event settings.

* Wayfinding and Safety: Corridor lights, stairwell sconces, and signage ensure guests can find the room safely and confidently at any hour reducing anxiety.

* Exterior and Parking Lighting: Well-lit exteriors deter security threats and help guests safely navigate parking lots and entrances at night.

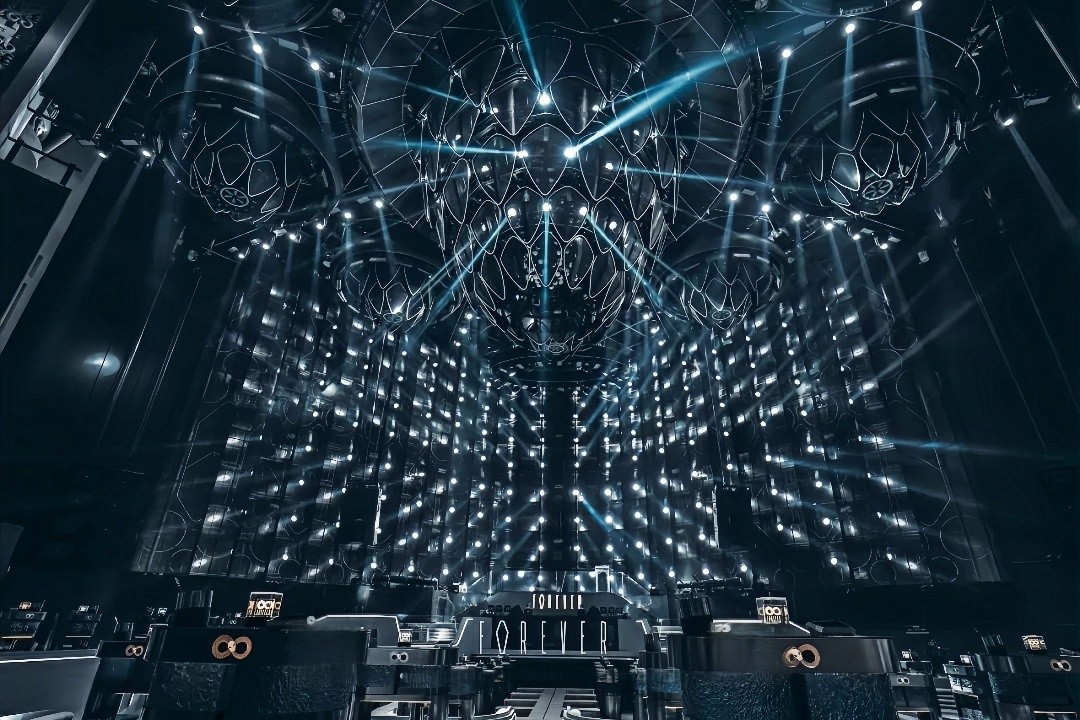

2. Create Ambiance and Emotional Connection

Lighting sets the mood and defines the character of a space, it's the invisible hand that guides guests' emotional journey from the moment they walk through the door.

* Mood Setting: Warm, soft lighting can make a boutique hotel feel intimate and relaxing, while bright, dynamic lighting can make a modern lifestyle hotel feel energetic and vibrant. Thoughtful lighting design improves comfort, which directly influences guest satisfaction, reviews, and repeat bookings.

* Zoning and Atmosphere: In restaurants and lounges, layered lighting creates intimacy and encourages relaxation. In guest rooms, the dimmable function allows guests to personalize their environment and feel at home.

* Brand Identity: Lighting schemes can subtly communicate a hotel's brand identity, the consistent design across guestrooms and public spaces reinforces brand recognition and strengthens the hotel's market positioning, ensuring the space aligns with the guest's expectations.

3. Elevate Design and Architecture

Hotels invest heavily in interior design, art, and architectural details. Lighting is the secret that brings these investments to life.

* Focal points: Strategic spotlighting can turn a beautiful lobby sculpture or a textured feature wall into a memorable visual highlight.

* Perceived Space: Well-placed, layered lighting can make small rooms feel larger and more open, while cove lighting can add depth and interest to high ceilings.

* Aesthetic Cohesion: Consistent and complementary lights tie the design elements together, creating a polished, curated look that guests associate with quality.

4. Drive Operational Efficiency and Sustainability

Lighting is a major operational expense for hotels.

* Energy Savings: To choose energy-efficient LED lighting can reduce a hotel's energy consumption by up to 70-80%, this translates to significant, long-term cost savings across hundreds of rooms and public areas.

* Maintenance Costs: Long-lasting lights and bulbs can reduce the frequency of bulb replacements and the associated labor costs.

Why Partner with Sunwin for Your Hotel Lighting?

As a major hotel project lamps supplier in China, Sunwin understands the importance of lighting in improving guest's experience and your property's success. Here we offer:

* Custom Made Lights: Lights tailored produced to your brand's unique aesthetic and functional needs.

* Hotel-Grade Durability: Products engineered to withstand the rigors of high-traffic environments.

* 100% Support: From prototyping to global delivery and after-sales service.

Illuminate your hotel's potential with Sunwin, let's create spaces that guests remember and return to. Contact Us Today sales@sunwinhotellighting.com to discuss your next project!