From Qatar 2022 to North America 2026 Outdoor Advertising Solutions for the FIFA World Cup

1. The World Cup as a Global Advertising Stage

Every FIFA World Cup is more than a football tournament—it is also a global marketing festival. In 2026, the World Cup will be jointly hosted by the United States, Canada, and Mexico, marking the largest edition in history with 48 teams and 16 host cities. For sponsors, cities, and event organizers, this means massive demand for outdoor advertising displays that can deliver impact, reliability, and innovation.

2. Our Experience at Qatar 2022

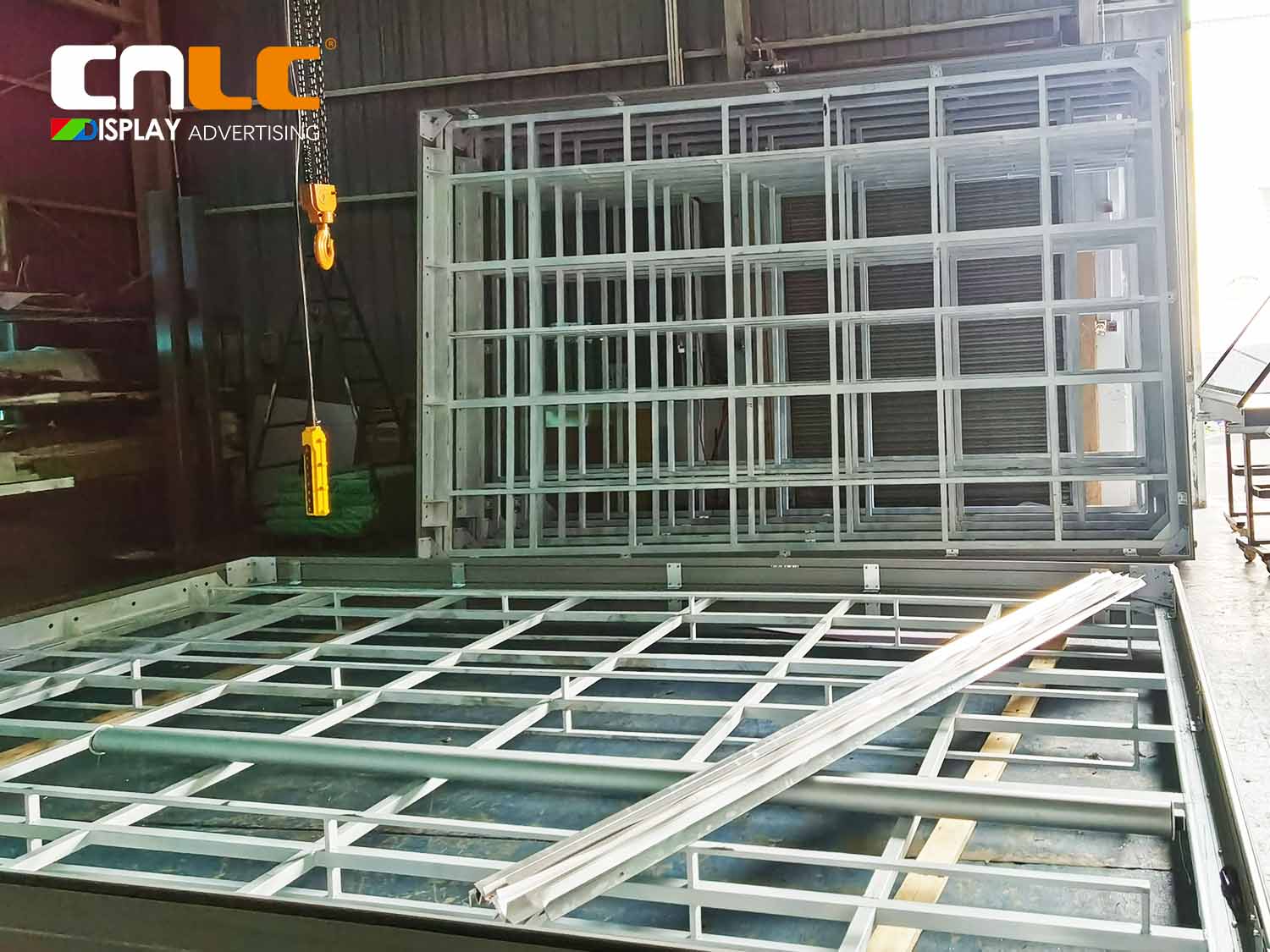

At the 2022 World Cup in Qatar, CNLC successfully delivered dynamic light boxes that created a vibrant city atmosphere and amplified sponsor visibility. These projects proved our capability to provide customized, large-scale advertising solutions for world-class events.

3. Expanding Beyond Dynamic Light Boxes

Building on our success in 2022, CNLC now offers a comprehensive portfolio of outdoor advertising products suitable for World Cup 2026 projects:

-

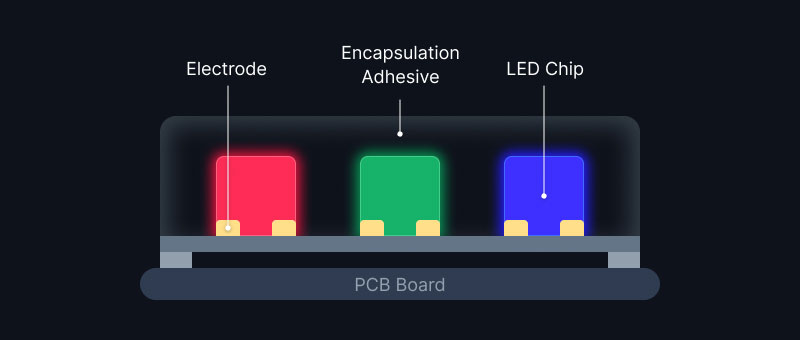

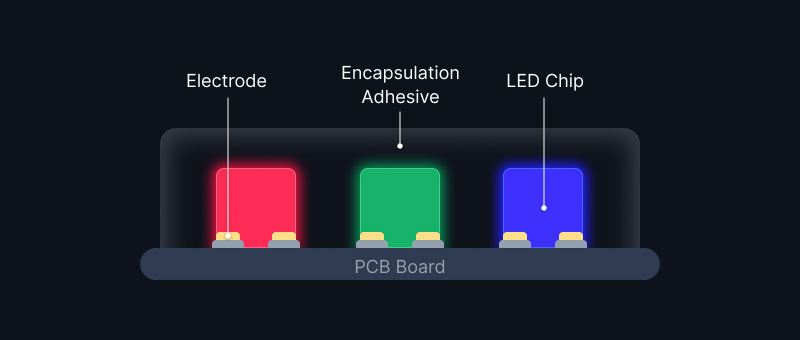

LED Billboards – High-brightness, weatherproof large displays for stadiums, highways, and fan zones.

-

LED Totems – Stylish vertical displays for streets, commercial districts, and public plazas.

-

LCD Digital Displays – Ultra-clear, high-definition signage for transport hubs, retail areas, and sponsor activations.

-

Dynamic Light Boxes – Dynamic illuminated signs that enhance atmosphere and attract crowds.

With these solutions, we support cities and brands in building a multi-layered advertising ecosystem that maximizes visibility during the World Cup.

-

Comprehensive outdoor advertising solutions for global events

4. Opportunities for World Cup 2026 Host Cities

From New York and Los Angeles to Toronto and Mexico City, every host city will face unique advertising challenges and opportunities. CNLC products are designed to meet these needs:

-

High brightness and clarity for both daytime and nighttime visibility.

-

IP-rated, weatherproof structures to withstand outdoor conditions.

-

Energy-efficient LED and LCD technology supporting sustainability goals.

-

Customizable formats to match stadium, fan zone, and city branding requirements.

5. CNLC: Ready for World Cup 2026 Projects

With over 18 years of experience in outdoor advertising solutions, CNLC is ready to partner with event organizers, sponsors, and municipalities to deliver innovative, reliable, and visually striking displays for the 2026 FIFA World Cup.

6. Conclusion

The countdown to FIFA World Cup 2026 has already begun. Cities and sponsors aiming to capture global attention must invest in advanced advertising technologies. CNLC stands ready with LED billboards, LED totems, LCD displays, and dynamic light boxes, helping transform urban landscapes into unforgettable World Cup experiences.

👉 Contact CNLC today to discuss customized outdoor advertising solutions for FIFA World Cup 2026.