How Outdoor LED Net Lights and Waterproof Icicle Lights Enhance Daily Streets and Parks

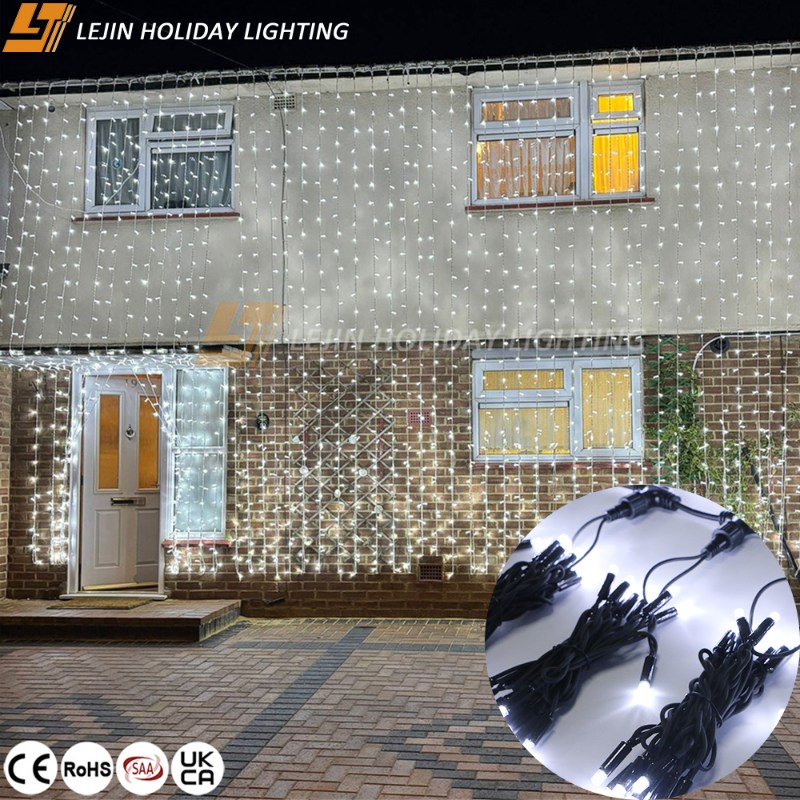

In landscape decoration projects for streets and parks, outdoor LED net lights, with their large-area grid coverage, cast a soft, uniform glow like a hazy light veil over large structures such as street trees and scenic corridors, creating an immersive light backdrop. Meanwhile, waterproof icicle lights, with their carefully designed hanging spacing, drape naturally over linear areas like building eaves and railings, precisely filling visual gaps in the space. One spreads, one hangs; one covers in a sheet, one accents in lines—together they form a richly layered light layout. Whether it’s street trees along main roads or rest pavilions in community parks, every corner is embraced by this harmonious light, solving the problem of light gaps caused by traditional single-lighting setups. From dusk till late night, public spaces maintain a consistent, warm visual feel, with every corner glowing softly.

Engineering-grade net lights with high-quality LED sources have their brightness carefully calibrated to meet road lighting safety standards. They provide ample yet gentle illumination for pedestrian-heavy sidewalks and leisure trails, ensuring clear visibility and safe movement at night without harsh glare. Waterproof icicle lights, with their directional light design, cleverly focus light on key landscape features like flower bed edges and sculpture outlines, making these spots stand out in the dark while avoiding wasteful light spillage. This "basic lighting for safety + focused highlighting for beauty" combination meets both the functional needs of public space activities and, with flexible warm white/cool white options, adapts to decorative themes across seasons and projects. It achieves a perfect balance between utility and aesthetics, where every light serves both purpose and beauty.

Outdoor spaces face challenges like wind, rain, and temperature swings—and net lights and icicle lights are built to withstand them. All-weather net lights are made of tough, tear-resistant oxford fabric, staying structurally stable even after long-term exposure to sun, wind, and rain. Weatherproof icicle lights feature fully sealed casings and waterproof glue technology, achieving professional waterproof standards to handle rain and snow effortlessly. Long-term testing confirms their excellent rust resistance, too. Both use low-energy drivers, maintaining stable brightness over time with no significant dimming, greatly reducing maintenance frequency and costs. Whether in scorching summers or freezing winters, these lights keep performing, ensuring decorative effects last, sparing project clients from frequent replacements and repairs.

Tailored to varied project needs, net lights and icicle lights excel in flexible, user-friendly installation. Net lights can be customized to fit tree shapes, corridor spans, and other specific dimensions, equipped with easy-tighten fixing systems that require no complex tools—one person can quickly cover a single tree or a section of corridor. Icicle lights use modular plug-in designs, with adjustable single-string lengths and easy multi-string connections, adapting to linear structures like street railings and park walls. No professional equipment or complicated wiring is needed; compared to traditional decorative lights, installation time is significantly reduced. Whether for tight-schedule street renovations or multi-scene park decorations, deployment is fast, meeting diverse project timelines.

Integrated with smart control systems, smart outdoor net lights and adjustable icicle lights easily connect to municipal lighting management systems for flexible mode adjustments. In daily mode, they run at a soft, low brightness, creating a quiet, cozy atmosphere in streets and parks—perfect for residents’ evening walks and chats. For special occasions like community fairs or holiday celebrations, a simple operation switches them to high-brightness mode, activating synchronized flickering, chasing, and other dynamic effects to instantly infuse the space with joy. This no-rework scene-switching ability frees streets and parks from single-function limitations, adapting to diverse activity needs and boosting public space reuse.

Practical project cases show that public areas decorated with energy-efficient net lights and decorative icicle lights often attract more residents to stay at night, with significantly higher participation in community activities. The soft light environment makes nighttime public spaces more transparent, enhancing surveillance clarity and reducing safety risks, letting residents feel safer during activities. Moreover, their unified, harmonious visual style strengthens regional identity, turning streets and parks into memorable community landmarks. With low-energy designs meeting green building standards, they cut energy use while creating a warmer, more welcoming public space—making light a warm bond connecting people, space, and community.