Exploring the Market Potential of 3 Way Terminal Blocks

Introduction:

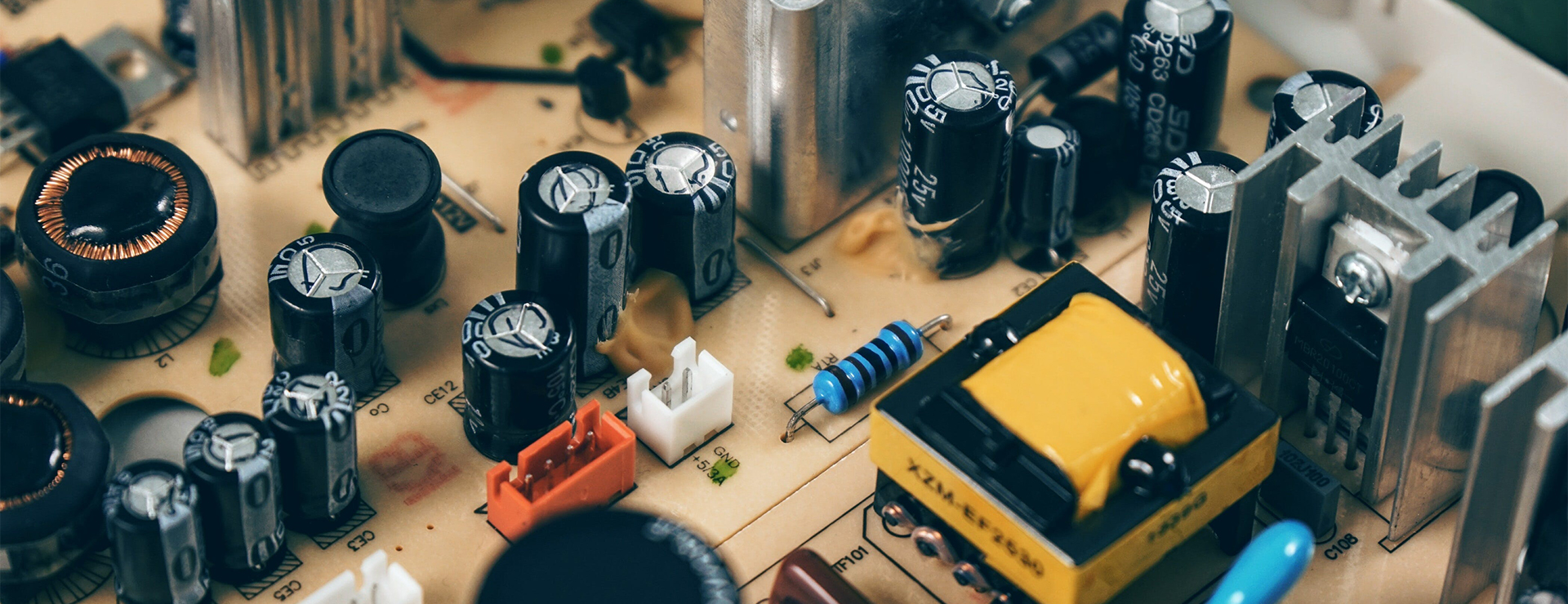

In today's rapidly evolving technological landscape, the demand for efficient and reliable electrical connections continues to grow. One product that plays a crucial role in various industries is the 3 way terminal block. Designed to facilitate secure and organized terminal 3 pin, these terminal blocks offer immense potential in ensuring smooth operations for various applications. This article delves into the market prospects and benefits of 3 way terminal blocks.

Versatile Applications of 3 Way Terminal Blocks:

3 way terminal blocks find extensive applications in industries such as automation, machinery, and electrical systems. With their capability to accommodate multiple connections, terminal block 3 pin provide a reliable solution for complex wiring setups. Whether it's connecting sensors, actuators, or control devices, the versatility of 3 pin screw terminal block connector makes them essential components in today's advanced systems. Manufacturers like HONG YI-HOMNECKS cater to diverse industrial needs by offering a range of high-quality terminal block options, including 3-pin variants.

Enhanced Connectivity with 3 Pin Screw Terminal Block Connectors:

The integration of screw terminal block connectors simplifies the installation and maintenance processes of 3 way terminal blocks. By utilizing screw-based connections, these terminal blocks ensure secure and vibration-resistant electrical contacts. The 3 pin screw terminal block connectors provide a reliable and stable interface, minimizing the risk of loose connections and electrical faults. Users can trust HONG YI-HOMNECKS' expertise in providing top-notch terminal block connector 3 pin connectors for seamless connectivity.

Streamlined Wiring with 3 Pin Terminal Block Connectors:

Terminal block connectors with 3 pins bring efficiency and convenience to wiring tasks. By offering a compact and organized solution for connecting multiple wires, these terminal blocks eliminate the messiness of individual wire connections. The design of 3 pin terminal block connectors enables easy identification and routing of wires, saving time during installation and future maintenance. HONG YI-HOMNECKS, a leading manufacturer and supplier in the industry, delivers high-quality 3 pin terminal block connectors for hassle-free wiring solutions.

Increased Reliability of 3 Way Terminal Blocks:

The reliability of electrical systems heavily depends on the quality of terminal blocks used. 3 way terminal blocks offer exceptional durability, ensuring long-lasting performance in demanding environments. With features such as corrosion-resistant materials and robust construction, these terminal blocks provide a secure and stable connection, even in harsh conditions. HONG YI-HOMNECKS, renowned for its commitment to quality, ensures that their 3 way terminal blocks meet industry standards, enhancing system reliability and minimizing downtime.

Future Market Trends and Opportunities:

The market for 3 way terminal blocks is poised for significant growth as industries continue to demand reliable and efficient electrical connections. Rapid advancements in automation, smart devices, and renewable energy systems fuel the need for innovative terminal block solutions. Manufacturers like HONG YI-HOMNECKS, with their dedication to research and development, are at the forefront of introducing advanced 3-way terminal block technologies and expanding their product offerings. As the industry evolves, the demand for versatile, high-quality, and feature-rich 3 way terminal blocks is expected to soar.

The market outlook for 3 way terminal blocks is immensely promising due to their versatile applications and significant benefits in electrical connectivity. With the convenience of 3 pin screw terminal block connectors and the seamless wiring facilitated by 3 pin terminal block connectors, these components are crucial for ensuring reliable and efficient electrical connections. As the market continues to evolve, HONG YI-HOMNECKS, a trusted terminal block manufacturer and supplier, remains committed to meeting industry demands through their premium range of 3 way terminal blocks and associated connectors, solidifying their position as a leader in the field.